MAYO WATER BLAST CABINETS

- Home

- :

- Post Casting

- :

- Mayo Water Blast Cabinets

Mayo Water Blast Cabinets

Mayo Engineering have used their considerable investment casting process experience to design a range of

Water Blast Cabinets for Shell Removal.

These are in the main used by Blade, Turbo Wheel and Aluminium investment casting foundries.

The system comprises of 3 main parts..

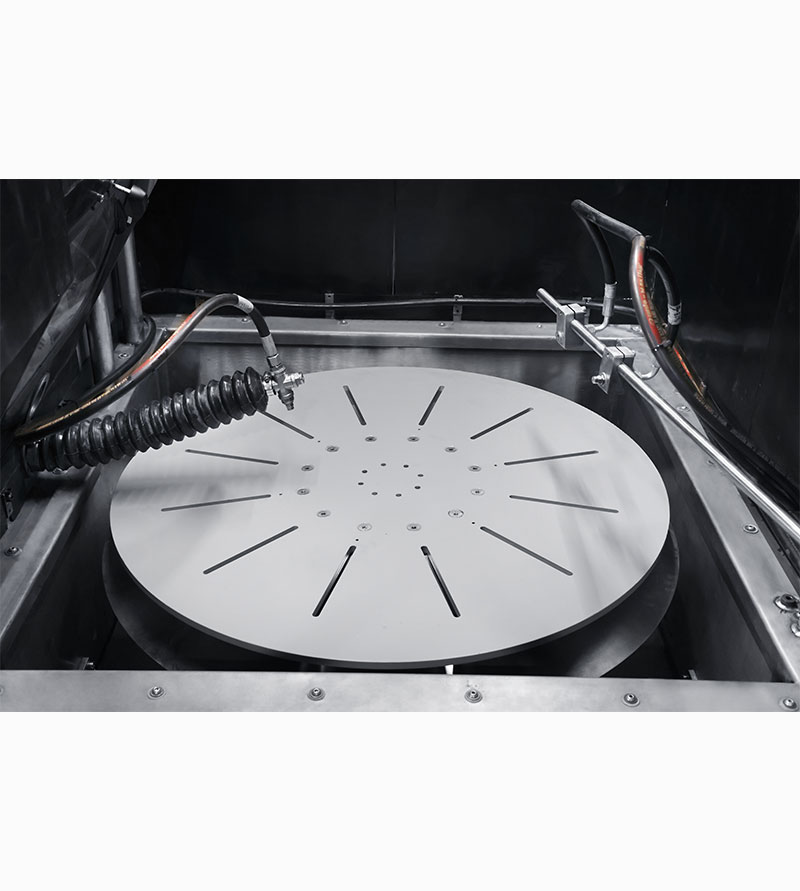

Firstly, the Mayo Blast Cabinet, this is a stainless steel cabinet with a both rotary and 60° tilting table, the actual water blasting operation is via the unique Mayo System 3 Blast Heads.

Whereas in the past this type of cabinet has one gimble mounted manual blast lance, which our latest design cabinets also have, but we have a further two automatic blast lances as well, so 3 water blast positions in all.

Secondly, the Mayo Pump Unit, this comprises of a skid mounted pump and motor assembly, coupled and tailored to the blast cabinet size, for example our 1500mm x 1200mm x 1200mm Blast Cabinet is coupled with an 11kw 150bar Speck-Triplex Pump

Thirdly, the Mayo Water Recirculation Module when selected, is designed to enable the Mayo Water Blast System to operate using recirculated water, and thus is both better for the environment, and cheaper to operate water costs wise,. The module comprises of a special designed unit that removes all but the most miniscule of shell particles.

These are in the main used by Blade, Turbo Wheel and Aluminium investment casting foundries.

The system comprises of 3 main parts..

Firstly, the Mayo Blast Cabinet, this is a stainless steel cabinet with a both rotary and 60° tilting table, the actual water blasting operation is via the unique Mayo System 3 Blast Heads.

Whereas in the past this type of cabinet has one gimble mounted manual blast lance, which our latest design cabinets also have, but we have a further two automatic blast lances as well, so 3 water blast positions in all.

Secondly, the Mayo Pump Unit, this comprises of a skid mounted pump and motor assembly, coupled and tailored to the blast cabinet size, for example our 1500mm x 1200mm x 1200mm Blast Cabinet is coupled with an 11kw 150bar Speck-Triplex Pump

Thirdly, the Mayo Water Recirculation Module when selected, is designed to enable the Mayo Water Blast System to operate using recirculated water, and thus is both better for the environment, and cheaper to operate water costs wise,. The module comprises of a special designed unit that removes all but the most miniscule of shell particles.